Counterfeiting In Manufacturing: Is Your Trash Being Illegally Recycled?

By: Karen Panetta (Forbes)

Good, Fast, Cheap -- pick two. Recycling and selling defective components is certainly fast and cheap. That's a shady, fraudulent practice but I'm not sure that counts as counterfeiting.

We have gotten into the habit of shipping our waste and scrap to poor countries; out of sight, out of mind. That's fast and cheap, too.

Years ago, we designed new products focused on desired operating features and cost. The slogan was "Good, Fast, Cheap, Pick-Two." Today, it seems like the slogan should be "Authentic, Fast, Cheap, Pick-Two."

Electronic chip counterfeiting is now a multi-billion-dollar business. Counterfeiters operate by getting their hands on defective parts and packaging that is discarded in manufacturers' trash or recycling bins. Consumers, manufacturers and small businesses are now suffering the ramifications of unknowingly selling and buying defective components. The only recycling done by counterfeiters is usually adding a fresh coat of paint on the defective parts with your company's logo on it, along with an attractive price tag that makes it sell faster than toilet paper during a pandemic.

Today's designers need to think about how to protect their designs from being exploited by the counterfeiters. Furthermore, companies need to prevent counterfeiters from gaining access to trash bins, and from recovering discarded junk and then re-selling it as good, cheap, authentic components.

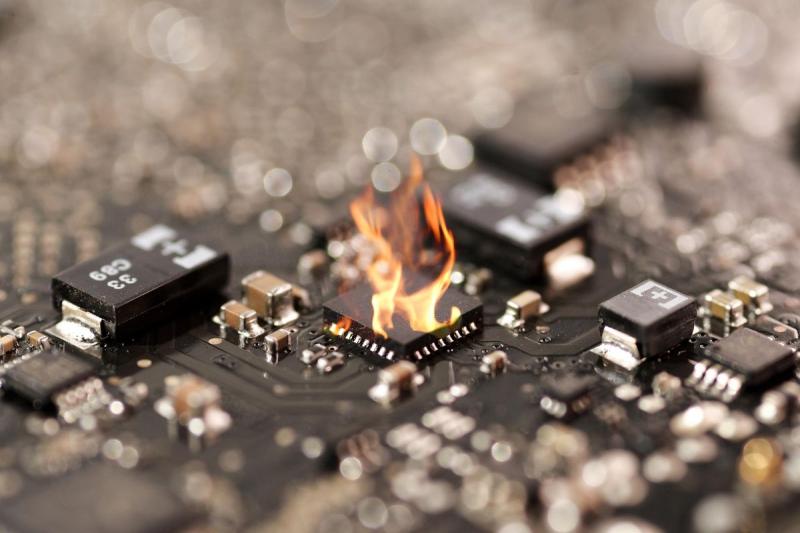

Anti-counterfeiting methods or counterfeit avoidance techniques attempt to detect and prevent illegal use of products, packaging and components. One extreme approach is to have the device self-destruct when it detects illegal usage, which is not something the consumer wants to experience should the counterfeit part make its way into a product we purchase. So why haven't manufacturers succeeded in thwarting counterfeiters?

First, including counterfeiting avoidance techniques in all products is very expensive, which ultimately increases the cost to consumers, and increases design and manufacturing time. Second, even with this anti-counterfeiting investment, the counterfeiters are getting smarter. Consider the case where one component manufacturer had a design defect in their component and the counterfeiters detected it and fixed it before the company itself released the new revision. These are some very talented counterfeiters who often have help from the inside.

But, this is not the worst of it. These bogus components are making their way back into our medical facilities and military equipment, where the components' failure could endanger lives and affect homeland security. Some outrageous examples include an incident where customers stockpiled components for future repairs to an aircraft and then when the new parts were needed, it was discovered that the component packages were totally empty. Unfortunately, this was discovered too late to hold a vendor responsible or to aid law-enforcement in tracking down the culprits.

I learned about counterfeiting when I became a victim. I was about to begin teaching a class and powered up my computer only to discover it hung. The screen displayed a wallpaper bearing the name of a component manufacturer. My students thought this was cool. They had never seen such a failure. This wasn't the typical "blue screen of death," it was the "curse of the counterfeit component." The computer manufacturer had used counterfeit components in their products and passed them on to their customers. The counterfeiting went undetected until a number of customers had experienced the same failure.

Right now we have very little confidence that our products, and components used in our products, are authentic and worse, we have little recourse when we become a victim of counterfeiting.

We need engineering superheroes who excel at ensuring designs are immune to counterfeiting. They will help guarantee product authenticity by including robust anti-counterfeiting techniques, that won't set us on fire when we discover them.

In the future, engineering institutions and industry will build stronger collaborations to train and develop this future generation of anti-counterfeiting superheroes. In the meantime, it's important to ensure that manufacturers truly destroy their discarded products to keep them from ever being revived and sold illegally. This also means having robust validation and quality testing procedures in place for any components or supplies they purchase from vendors that ultimately end up in their systems and products.

Tags

Who is online

58 visitors

Good, fast, cheap. As a nation we've already picked two. Everything we do must be fast and cheap. We can always blame someone else when those choices bite us on the backside.