Recycling Lead-Acid Batteries Is Easy. Why Is Recycling Lithium-ion Batteries Hard? - CleanTechnica

By: James Morton Turner (CleanTechnica)

The rise in lithium products with their associated heavy metals begs the question, "What do we do when the battery loses its capacity? "

The lithium-ion batteries in today’s electric vehicles outperform older lead-acid batteries by almost every measure, except one. Lead-acid batteries are still the single-most recycled product in the world.

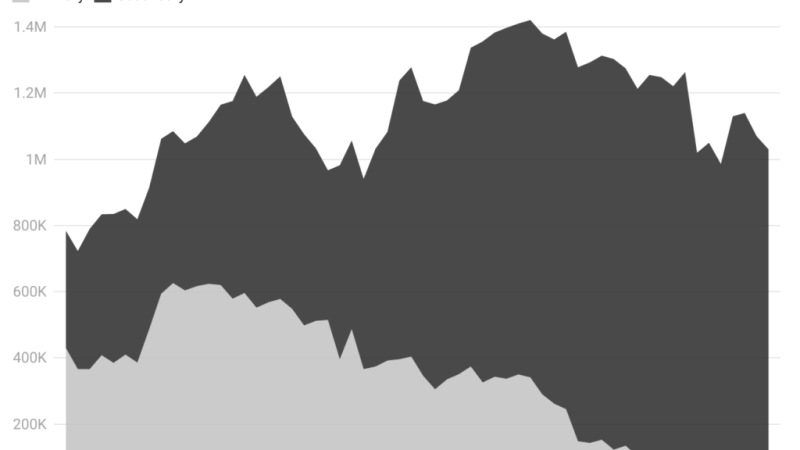

Although lithium-ion batteries are set to power a clean-energy transition, more than 100 million lead-acid batteries are still sold each year in the United States, mostly as starter batteries for cars, trucks, and boats.

When those lead-acid batteries die, nearly all of them get recycled. In fact, the lead-acid battery industry claims a domestic recycling rate of 99 percent. In 2021, the U.S. produced nearly one million metric tons of recycled lead. Almost all of that recycled lead was used to manufacture new batteries.

First seed from my phone. We'll see if I throw the in the woods

You don't have to throw the phone in the woods, the article is fine.

I read an article a few months ago on how some of the larger corporations that are working on recycling lithium batteries and one facility in CA is already doing it. Hopefully, we'll get to the same percent of recycling lithium batteries as we do with the current lead batteries.

Yes, hopefully we will. There are more/ different chemistries and metals, so it will be interesting to see how they deal with the separation aspect.

Since, barring some unforeseen technical breakthrough, these batteries are going to be a large component of the economy, I wonder just who is researching and how much capitalization they have towards a solution? Seems like the larger energy brands would have a significant interest in doing so.

Here is a good article on some companies that are starting to invest in recycling lithium battereies and a few are already building plants to do so.

This is incredible: (from your source)

A whole new technology of EV car batteries are being said to hit the market by late 2024 or 2025.

Most of the tech looks to have moved from Lithium-Ion to various silicon techs. Silicon can hold charges longer, but until now didn't charge well. We have companies with silicon-anode power units, a silicon wire anode, silicon-dominant anode, and a porous, sponge-like silicon anode. This last tech is being tested in cars by Renault, Nissan and Mitsubishi.

The University of Texas is working on a lithium-ion battery that doesn’t use cobalt as a cathode. Instead, it uses up to 89 percent nickel as well as aluminum and manganese. A Chinese company is manufacturing cobalt-free batteries for the EV market. They claim a higher energy density, resulting in a range of up to 500 miles on a charge.

IBM Research's new battery is free of heavy metals and can out-perform lithium-ion batteries. They extract material from seawater. The batteries will be cheaper to make, can charge faster, and pack in higher energy density and power. Mercedes-Benz is backing this project.

There are a slew of other tech across the world working on better batteries including powering cars by wi-fi, ultrasound, biological semi-conductors, solid state, nano wires, Zinc-air, and more.

If they hit the mark it will be incredible.